Prevent Costly Breakdowns with HVAC Diagnostic Tests

Table of Contents

- Introduction

- What Are HVAC Diagnostic Tests?

- Importance of HVAC Diagnostic Tests

- Types of HVAC Diagnostic Tests

- Visual Inspection

- Electrical Component Testing

- Refrigerant Level Check

- Airflow Analysis

- System Performance Testing

- Common Issues Detected by HVAC Diagnostic Tests

- Steps for Conducting an HVAC Diagnostic Test

- FAQs

- Conclusion

Introduction

HVAC systems are the backbone of indoor comfort, ensuring optimal temperature and air quality in residential and commercial spaces. However, like any complex machinery, HVAC systems are prone to wear and tear, which can lead to inefficiencies or complete breakdowns. This is where HVAC Diagnostic Tests come into play. These tests are crucial for identifying issues within the system, enabling efficient repairs and maintenance, and ensuring that the system operates at peak performance.

What Are HVAC Diagnostic Tests?

HVAC Diagnostic Tests refer to a series of assessments and evaluations performed on heating, ventilation, and air conditioning (HVAC) systems. These tests aim to pinpoint issues that may not be immediately visible, such as electrical faults, airflow obstructions, refrigerant leaks, or component malfunctions. By systematically checking each part of the system, HVAC technicians can diagnose problems accurately and recommend the appropriate repairs.

Importance of HVAC Diagnostic Tests

Conducting regular HVAC Diagnostic Tests is essential for several reasons:

- Preventive Maintenance: Early detection of potential issues can prevent costly repairs or system failures.

- Efficiency Optimization: Identifying inefficiencies helps improve system performance, reducing energy consumption and lowering utility bills.

- Longevity of Equipment: Regular diagnostics can extend the lifespan of HVAC systems by ensuring that all components function correctly.

- Enhanced Comfort: A well-maintained system provides consistent temperature control and better indoor air quality.

Types of HVAC Diagnostic Tests

Visual Inspection

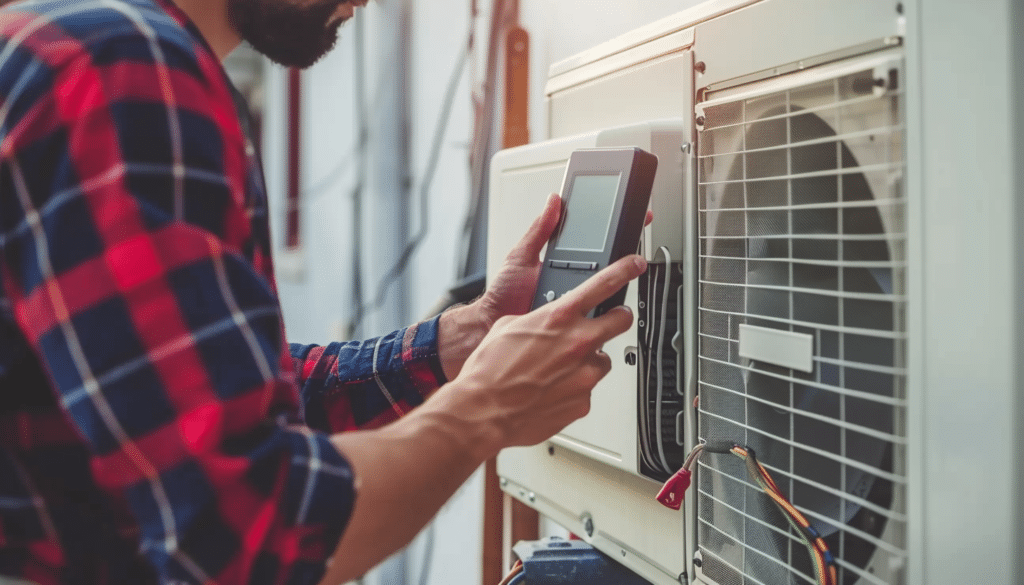

A visual inspection is the first step in any HVAC Diagnostic Tests. Technicians visually examine the entire system for signs of wear, corrosion, or damage. This includes checking the condition of filters, ducts, vents, and external components like compressors and fans.

- What to Look For:

- Dirty or clogged filters

- Rust or corrosion on components

- Visible signs of leaks or cracks

Electrical Component Testing

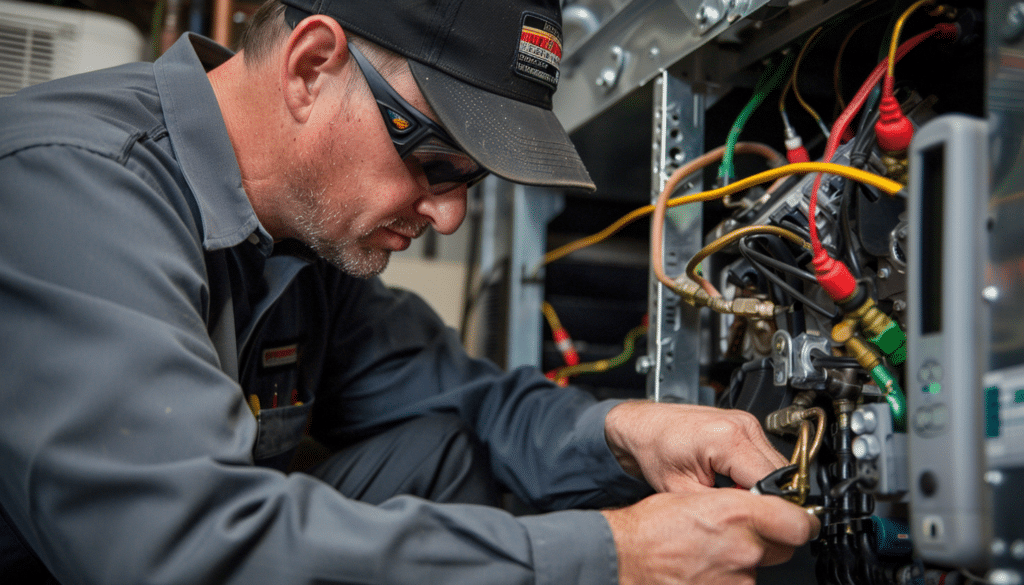

Electrical components, including thermostats, capacitors, and wiring, are critical for the proper operation of an HVAC system. Technicians use multimeters and other tools to test these components for continuity, voltage, and resistance.

- Key Checks:

- Thermostat accuracy and operation

- Continuity in wiring and connections

- Capacitor and relay function

Refrigerant Level Check

The refrigerant is essential for the cooling process in HVAC systems. Low refrigerant levels can indicate leaks or inefficiencies. Technicians use gauges to measure the refrigerant levels and ensure they match the system’s specifications.

- Symptoms of Low Refrigerant:

- Reduced cooling efficiency

- Ice formation on evaporator coils

- Unusual hissing sounds

Airflow Analysis

Proper airflow is crucial for the efficiency of an HVAC system. Technicians measure the airflow through ducts and vents to identify any blockages or leaks that could hinder performance.

- Tools Used:

- Anemometers for measuring air velocity

- Smoke pens to detect leaks

- Pressure gauges for duct pressure assessment

System Performance Testing

This involves running the HVAC system to monitor its overall performance. Technicians observe the system’s response to different settings, checking for irregularities in temperature control, noise levels, and operational efficiency.

- Performance Indicators:

- Time taken to reach desired temperature

- Uniformity of temperature distribution

- System noise during operation

Common Issues Detected by HVAC Diagnostic Tests

HVAC Diagnostic Tests can reveal a variety of common issues, including:

- Refrigerant Leaks: Identified by low refrigerant levels or the presence of ice on coils.

- Electrical Failures: Detected through faulty thermostats, blown fuses, or damaged wiring.

- Airflow Blockages: Caused by clogged filters, obstructed ducts, or closed vents.

- Component Wear and Tear: Such as worn-out belts, bearings, or motors.

- Poor Efficiency: Due to improper calibration or malfunctioning sensors.

Steps for Conducting an HVAC Diagnostic Tests

- Initial Assessment: Begin with a customer interview to understand the issues. Document any symptoms or irregularities noticed by the user.

- Visual Inspection: Examine the system’s exterior and accessible internal components for obvious signs of damage or wear.

- Electrical Testing: Use appropriate tools to check the continuity, resistance, and voltage of electrical components.

- Refrigerant Level Check: Measure the refrigerant levels to ensure they are within the manufacturer’s recommended range.

- Airflow Measurement: Assess the airflow through the system’s ducts and vents using specialized instruments.

- Performance Testing: Operate the system under normal conditions and observe its performance, noting any irregularities.

- Report Findings: Compile a detailed report of all findings, including recommended repairs or maintenance actions.

FAQs

Q1: How often should HVAC Diagnostic Tests be conducted?

A1: Ideally, HVAC Diagnostic Tests should be performed annually, especially before the start of the heating or cooling season, to ensure the system is ready for peak performance.

Q2: Can HVAC Diagnostic Tests improve energy efficiency?

A2: Yes, by identifying and addressing inefficiencies, these tests can help reduce energy consumption and lower utility bills.

Q3: What should I do if my HVAC system fails a diagnostic test?

A3: If a failure is detected, it’s essential to follow the technician’s recommendations for repairs or replacements to prevent further damage or inefficiency.

Q4: Are HVAC Diagnostic Tests covered under regular maintenance contracts?

A4: Many HVAC service contracts include diagnostic tests as part of routine maintenance. It’s advisable to confirm this with your service provider.

Q5: Can I perform HVAC Diagnostic Tests myself?

A5: While basic visual inspections can be done by homeowners, detailed diagnostic tests require specialized tools and expertise and should be performed by trained professionals.

Conclusion

HVAC Diagnostic Tests are a critical component of maintaining a healthy and efficient heating and cooling system. By identifying issues early, these tests help prevent costly repairs, extend the lifespan of the equipment, and ensure optimal performance. Whether you are a homeowner looking to maintain your comfort or a business owner ensuring a conducive environment, regular HVAC diagnostics are a wise investment. Remember, a well-maintained HVAC system not only enhances comfort but also contributes to energy savings and environmental sustainability.

For reliable HVAC services, including diagnostics, repairs, and installations, consider reaching out to professionals who understand the intricacies of your system and can provide tailored solutions to meet your needs.